Researchers at the university of Delaware (UDEL) are using the XJet Carmel 1400 3D printer to develop a new 5G antenna.

Israeli 3D printing company XJet announced the partnership earlier this week at RAPID + TCT, where CEO Hanan Gothait said: "the university of Delaware is a true pioneer in applying nanoparticle jet technology to antennas."

"" 5G promises to bring a real revolution in wireless technology and will bring connectivity, from supporting self-driving cars and smart cities to remote surgery, real-time streaming and virtual reality, and the prospect of an unlimited 'Internet of things'." "

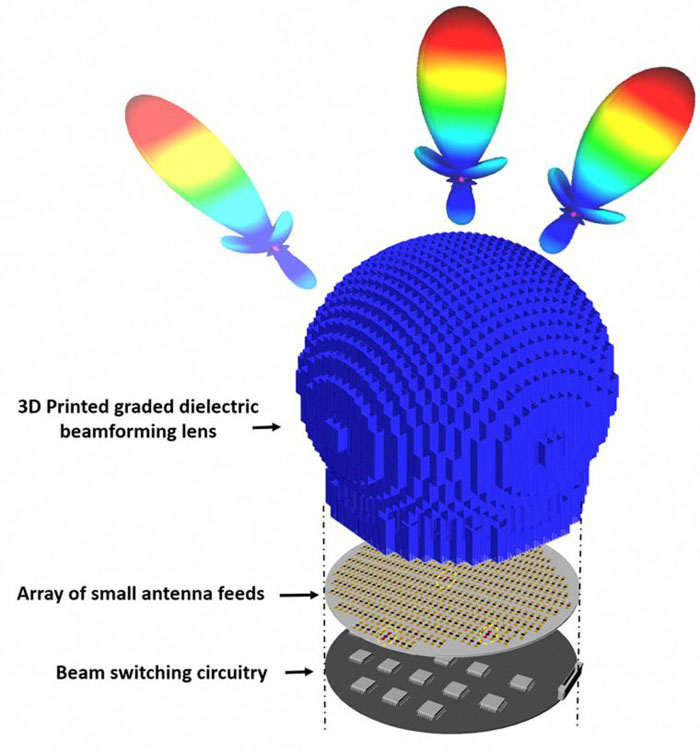

3D printing 5G antenna lens

5G signals, or fifth-generation mobile network technology, are said to transmit data 10 to 20 times faster than 4G and 3G. However, due to the sensitivity of 5G signals to objects, it needs to significantly increase the number of antennas.

Mark Mirotznik, a professor of electrical engineering at Udall university, and his team developed specialized software and algorithms for designing small, lightweight, low-cost 5G antennas, or passive beam controls. To make new antenna lenses with complex structures, small channels and material properties, they sought XJet's NPJ technology.

"" the discovery of XJet nanoparticle injection is a really exciting moment for us. "It solves at one stroke our previous frustration in achieving a combination of material properties and geometric properties. Professor Mirotznik added.

Passive beam control

Professor mirotschnik continued: "this is the only way to create the inner wall of each channel with enough precision and smoothness to keep the waves in the right direction, but this is done in ceramics."

"XJet's ceramics are isotropic, 100 per cent density ceramics with appropriate dielectric constants that do not 'absorb' and attenuate the signal. "It's no exaggeration to say that any small change in tolerance can cause the signal to go to the wrong place, and that's intolerable.

The antenna was developed at Youngstown state university in Ohio. Professor Eric MacDonald, chairman of manufacturing at YSU friedman, explained: "we conducted research to determine the properties and properties of XJet printed zirconia. This indicates that the crystal structure of the fingerprint is almost uniform.

"This opens up the possibility of 3D printing various microwave devices, including antennas, lenses and filters. Two simple dielectric resonator antennas are demonstrated with this material, which shows that the measured material properties can indeed be used in the precise design of such devices by electromagnetic simulation tools.